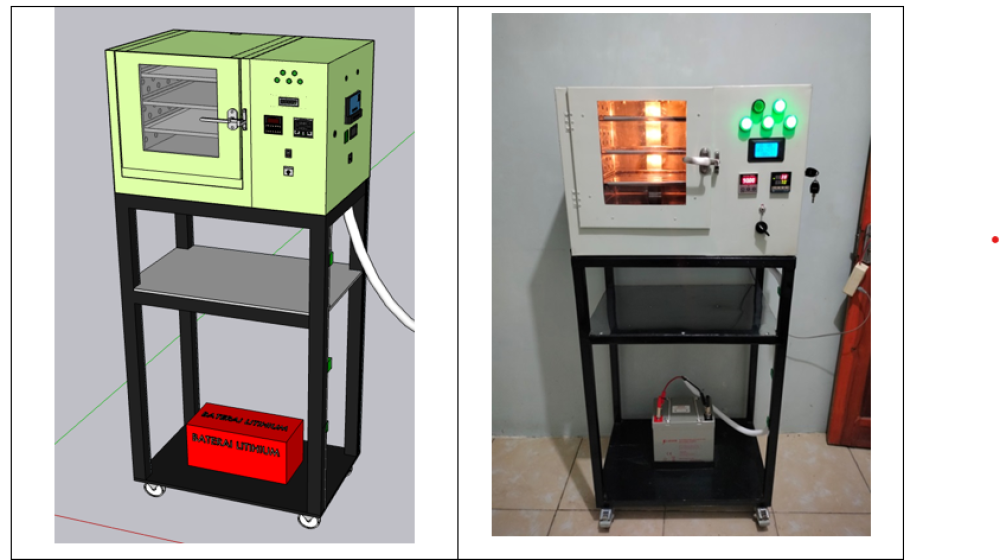

One part of the coconut that has not been utilized properly is the coconut fruit kentos. In some areas, coconut kentos is still seen as garbage/waste, even though coconut kentos has potential medicinal properties. In the process of making medicine, coconut kentos needs to be made into a simple form. Another challenge is that coconut kentos needs to be produced in clean conditions. Dryers with heating types through burning and/or direct drying from the sun are susceptible to contamination by other compounds. Therefore, one solution is to use an electric dryer that is better at maintaining the quality of coconut kentos simple. In addition, the availability of fresh coconut kentos is in coconut processing gardens that are far from the electricity network. Backup electrical energy is needed to meet this need. The purpose of this study was to create an electric coconut kentos simple dryer integrated with a PLTS system. The research method used is the development method (research and development). This method is a research method that is suitable for producing a particular product. In the development model will follow the model adapted based on the instructional design model "ADDIE" which consists of the stages of analysis, design, development, implementation and evaluation. The advantage of the tool to be made lies in the model that specifically follows the conditions of coconut kentos. The dryer model has also been integrated with the PLTS system to utilize solar energy which is generally available in tropical forest areas.